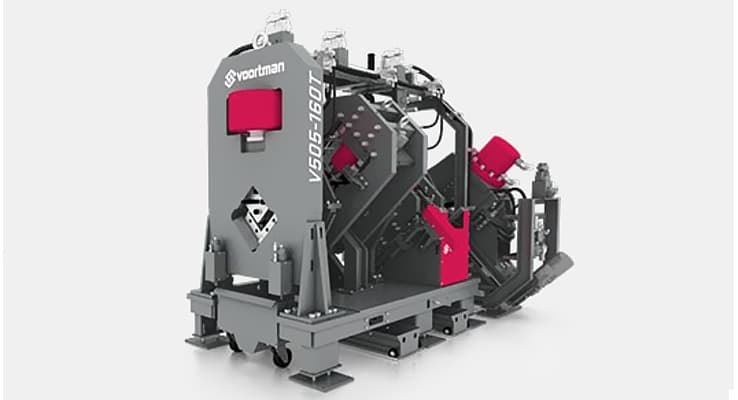

Beam Layout Welding Projects

It has a solid underside that holds the steel plate, while the weldheads pass through it. This is where the flanges on the H beam can be shaped and cut. The web is then created from a large piece of plate. It is then loaded onto a belt-like conveyor belt and the flanges are attached to it.